Why Use GFRC Panels?

GFRC (Glass Fiber Reinforced Concrete) panels are becoming increasingly popular in the construction industry due to their numerous benefits and versatility. These panels are made by mixing a special type of cement with fine aggregates, high-strength glass fibers, and water. The resulting material is strong, lightweight, and highly durable, making it an ideal choice for various applications. From architectural cladding and column covers to ornaments and decorative elements, GFRC panels offer designers and architects unparalleled design freedom and flexibility. In addition to their aesthetic appeal, these panels are also fire-resistant, weather-resistant, and require low maintenance. With their ability to replicate the appearance of natural stone, wood, or metal, GFRC panels provide a cost-effective alternative to traditional construction materials without compromising on quality or performance. Whether it is a new construction project or a renovation, the use of GFRC panels can enhance the overall look, durability, and sustainability of any building.

Applications

GFRC panels, or Glass Fiber Reinforced Concrete panels, offer numerous benefits that make them highly suitable for various industries and applications. These panels are widely used in architecture, engineering, defense, and building restoration projects.

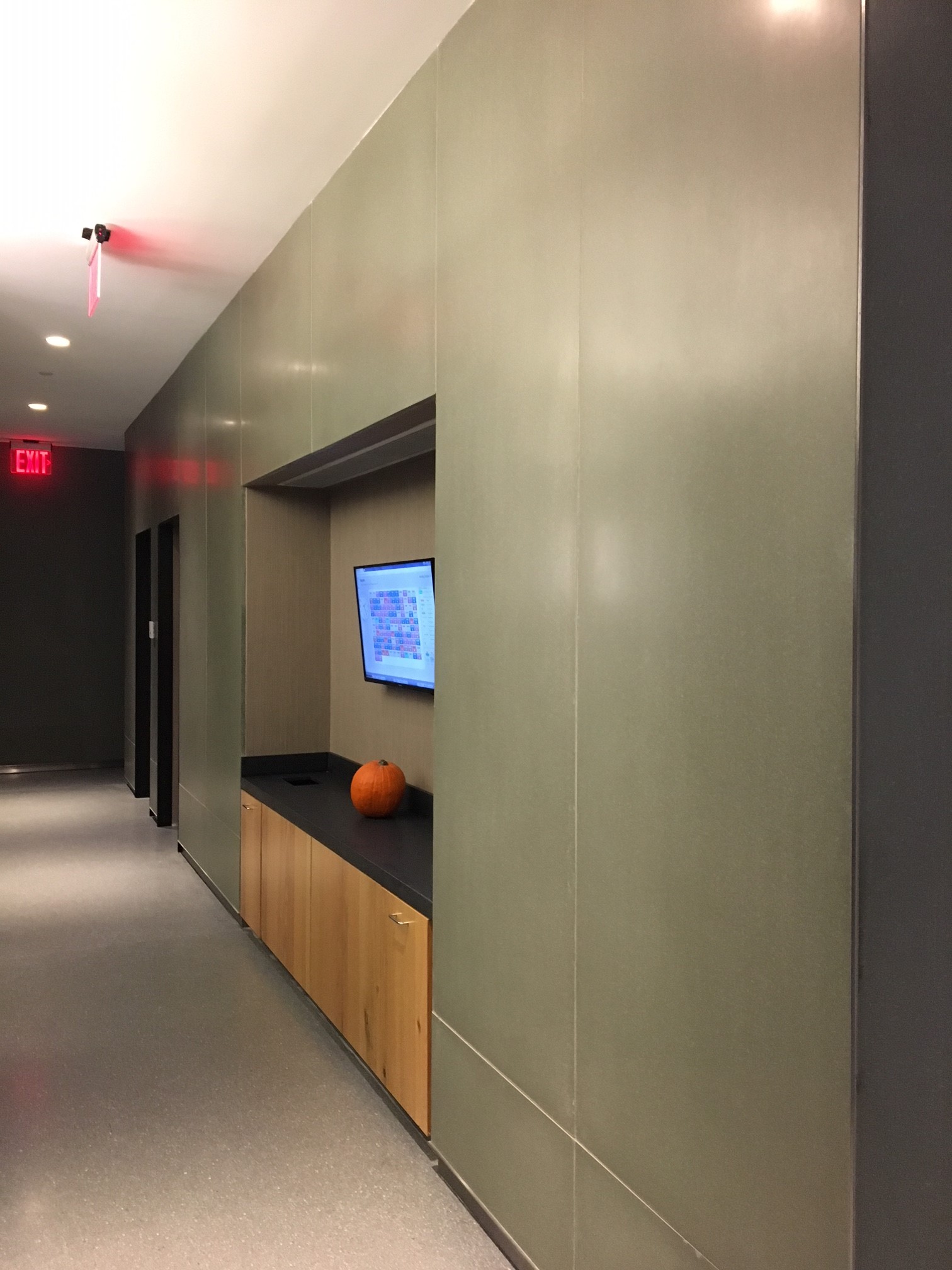

In architecture, GFRC panels find applications in the construction of exterior cladding, curtain walls, and decorative elements. They provide flexibility in design, enabling architects to create intricate patterns and shapes. Engineering projects also benefit from GFRC panels as they can be used for bridges, tunnels, railway platforms, and other structural elements. The panels’ strength and durability allow for large spans and heavy loads.

In building restoration projects, GFRC panels prove advantageous as they can emulate various historical architectural styles, providing an aesthetically pleasing result.

These panels continue to revolutionize construction practices and offer sustainable solutions for a range of projects.

Types of GFRC Panels

Panelized GFRC panels are a convenient and efficient option for construction projects that require the use of Glass Fiber Reinforced Concrete. These panels come pre-attached in groups on frames, making them easy to install and saving time and labor on-site. The panels can be customized to fit the specific design and structural requirements of a project, providing a seamless and durable solution for exterior cladding, facades, and other architectural elements. With panelized GFRC panels, builders can achieve a modern and sleek aesthetic while benefiting from the strength and performance of this innovative material.

Non-panelized GFRC panels are prefabricated architectural elements that are not assembled into panels before installation. These panels offer flexibility in design and can be customized to fit specific project requirements. Non-panelized GFRC panels are more suitable for projects that require unique shapes, sizes, or details that may not be feasible with traditional panelized systems. These panels are typically installed individually on-site, allowing for a more seamless integration into the overall design of the building.

Additionally, other materials such as sheet metal and foam board may be used to enhance specific characteristics. Sheet metal reinforcement is typically utilized to increase panel rigidity and impact resistance. Foam board insulation may be incorporated into GFRC panels to improve energy efficiency and thermal insulation properties.

Whether it be for large-scale projects or intricate architectural designs, GFRC panels offer versatility and durability to meet various construction needs.

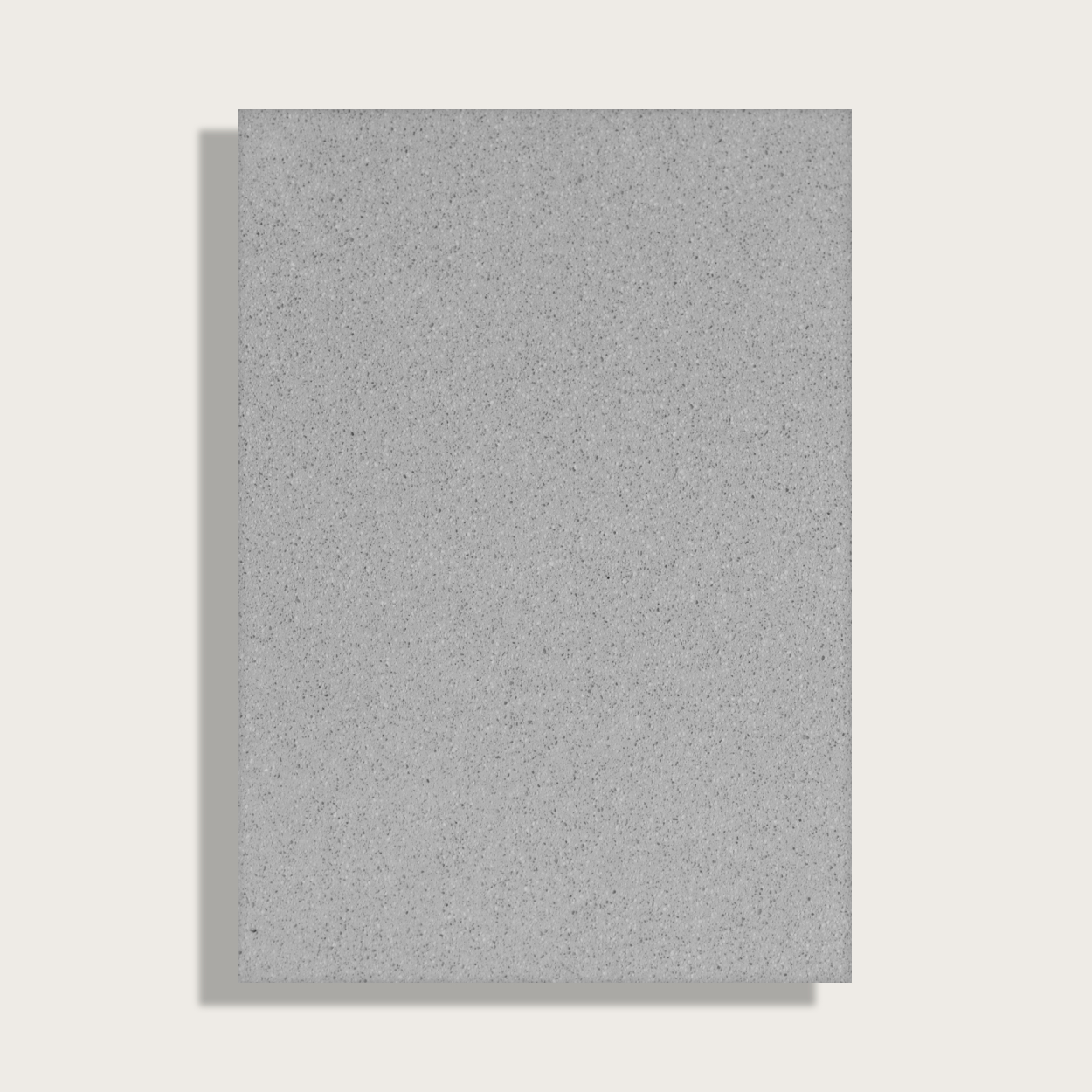

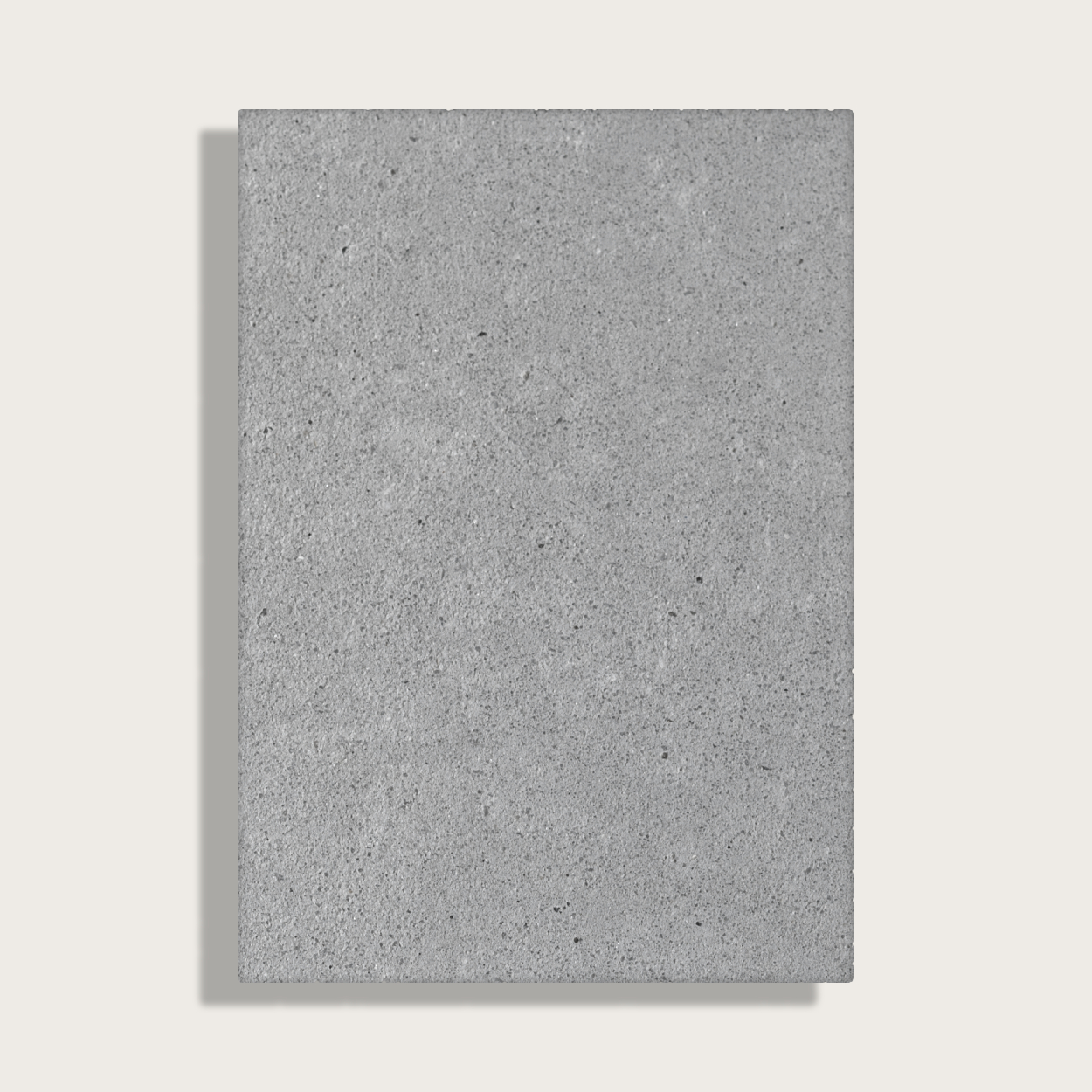

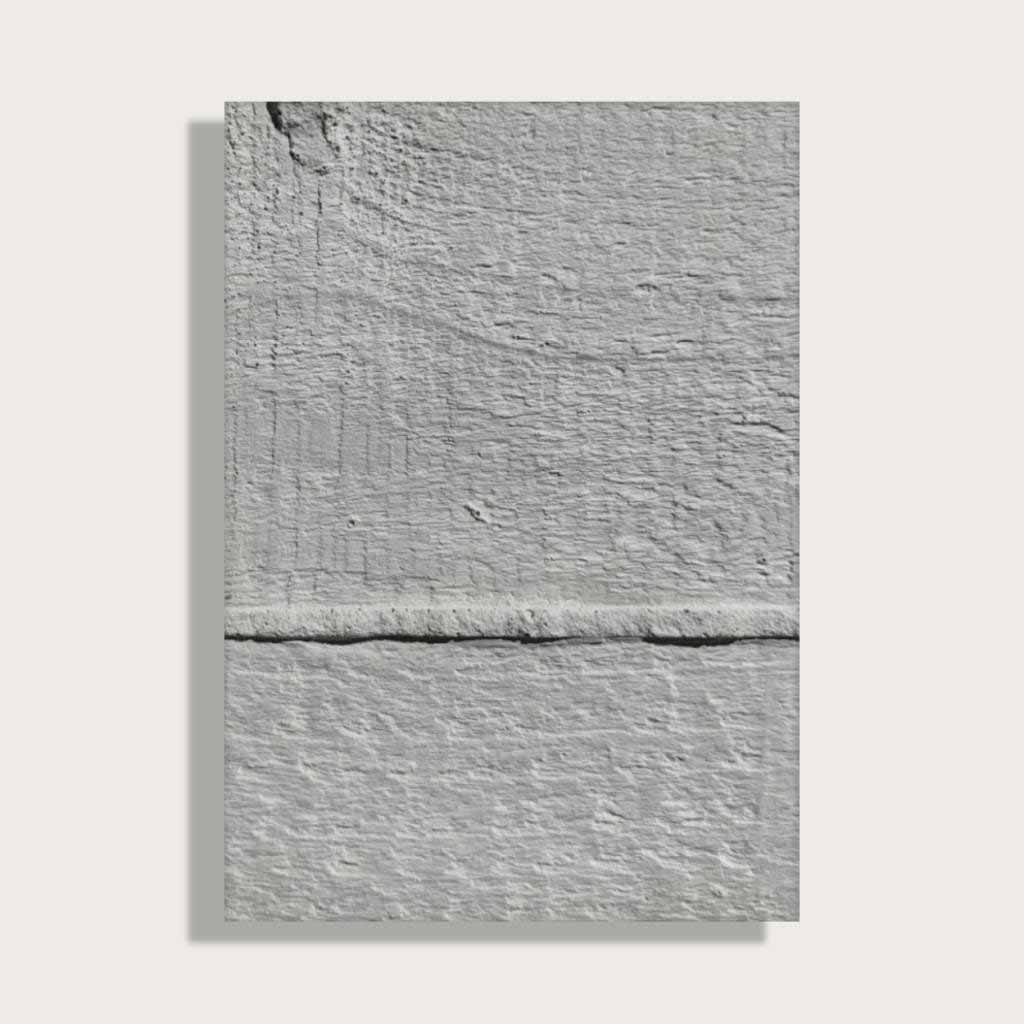

GFRC Textured Surfaces

GFRC panels, or Glass Fiber Reinforced Concrete panels, offer a wide range of textured surfaces that can be achieved to enhance the aesthetic appeal of a facade. These panels can mimic the look and feel of various materials, including wood, aggregate, masonry, and even geometric patterns.

One popular texture that can be achieved with GFRC panels is a wood-like finish. By incorporating wood grain patterns and texture into the panel molds, the resulting panels can closely resemble the appearance and feel of real wood. This allows for the incorporation of organic elements into the architecture, while still benefiting from the durability and versatility of concrete.

Additionally, GFRC panels can be designed to imitate aggregate surfaces, such as exposed aggregate concrete. This texture involves the use of small rocks or pebbles embedded in the concrete to create a rough and textured surface. This can add a sense of depth and visual interest to the facade.

Furthermore, GFRC panels can be used to create geometric patterns, ribs, waves, and other interesting designs on a facade. These textures can add a contemporary and dynamic element to a building’s architecture, breaking up the monotony of a flat surface.

It’s important to note that due to the use of natural materials in GFRC panels, there will be a natural variation in color and texture across the panels on a facade. This variation adds depth and visual interest to the overall design, creating a more organic and natural look.

Why Use Concreteworks East for Your Project?

When it comes to choosing a company for your project, Concreteworks East is a trusted choice.

Concreteworks East is backed by years of experience in the industry. Our extensive portfolio showcases our expertise and successful completion of projects in various industries, including residential, commercial, and hospitality. This demonstrates our versatility and capability to handle projects of any scale and complexity.

Alongside our experience, Concreteworks East has an unwavering commitment to quality. We prioritize delivering exceptional results and ensuring client satisfaction. Our team of highly skilled professionals uses state-of-the-art techniques and materials to ensure the longevity and durability of our concrete projects.

From custom concrete designs to precast fabrication and installation, we have the expertise to bring your vision to life. Our team works closely with clients to understand their specific requirements and provide tailored solutions that meet their needs effectively.

Choosing Concreteworks East for your project guarantees not only excellent results but also peace of mind. Our track record of successful projects, versatility, and commitment to quality make us the ideal choice for any concrete project.