Panel Styles

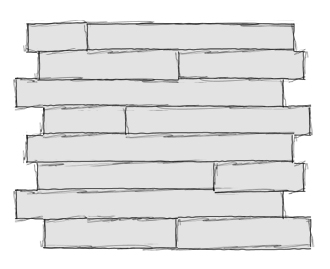

Coastal

Features a rough grain wood texture with intentional gaps between planks to allow the concrete to seep through.

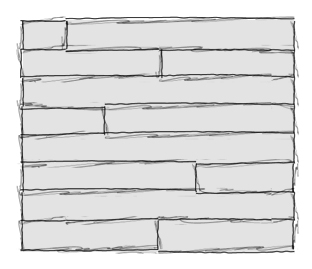

Alpine

Features a medium grain wood texture with tight fitment of individual planks for a more subtle board form finish.

Ceruse

Features a full sheet wood grain to the full extents of the precast panel.

Board Form Portfolio

Why Choose Board Formed Concrete Panels?

Choosing board formed concrete panels offers several benefits and advantages over other types of finishes for interior and exterior wall surfaces.

Firstly, board formed concrete panels provide a unique and visually appealing wood grain texture that adds a distinctive touch to any space. The natural variations and imperfections in the wood grain create a warm and organic look that cannot be replicated by other finishes. This texture can enhance the aesthetic appeal of both modern and traditional designs, making it a versatile choice for any style of architecture.

Additionally, board formed concrete panels have unique characteristics that make them highly durable and long-lasting. Unlike other materials, such as wood or paint, board formed concrete is resistant to rot, pests, and weathering. It is also fire-resistant, providing an added level of safety and peace of mind.

Furthermore, board formed concrete is a versatile option for various projects, from residential homes to commercial establishments. It can be used both indoors and outdoors, making it suitable for walls, columns, and facades. Its durability ensures that it can withstand high traffic areas and the elements, making it an ideal choice for both residential and commercial applications.

These qualities make them a popular choice for interior and exterior wall surfaces in a range of settings.

Board Form Concrete Panel Applications

Board form concrete panels have a wide range of applications, both for exterior and interior wall surfaces. These panels are often used in architectural projects to achieve a modern and industrial look.

Exterior wall surfaces can benefit from board form concrete panels due to their durability and ability to withstand extreme weather conditions. These panels can be used to create stunning facades for commercial buildings, residential homes, and even landscape structures like retaining walls or fencing. The natural texture created by the wood grain pattern of the formwork gives a unique aesthetic appeal to these structures.

When it comes to interior wall surfaces, board form concrete panels can be used to create a statement feature wall that adds a touch of sophistication to any space. Whether it is a residential living room, a restaurant, or a hotel lobby, these panels bring a sense of rawness and elegance to the interior design.

Additionally, board form concrete panels can be customized in terms of size, layout, and seam dimension to achieve different design concepts. These panels can vary in thickness, allowing for the creation of strong and solid walls. The layout of the boards can be adjusted to create unique patterns or designs on the surface. The seam dimension can also be altered to create different visual effects, such as emphasized lines or a seamless appearance.

Their customization options provide endless possibilities for achieving different design concepts, making them a popular choice in contemporary architecture.