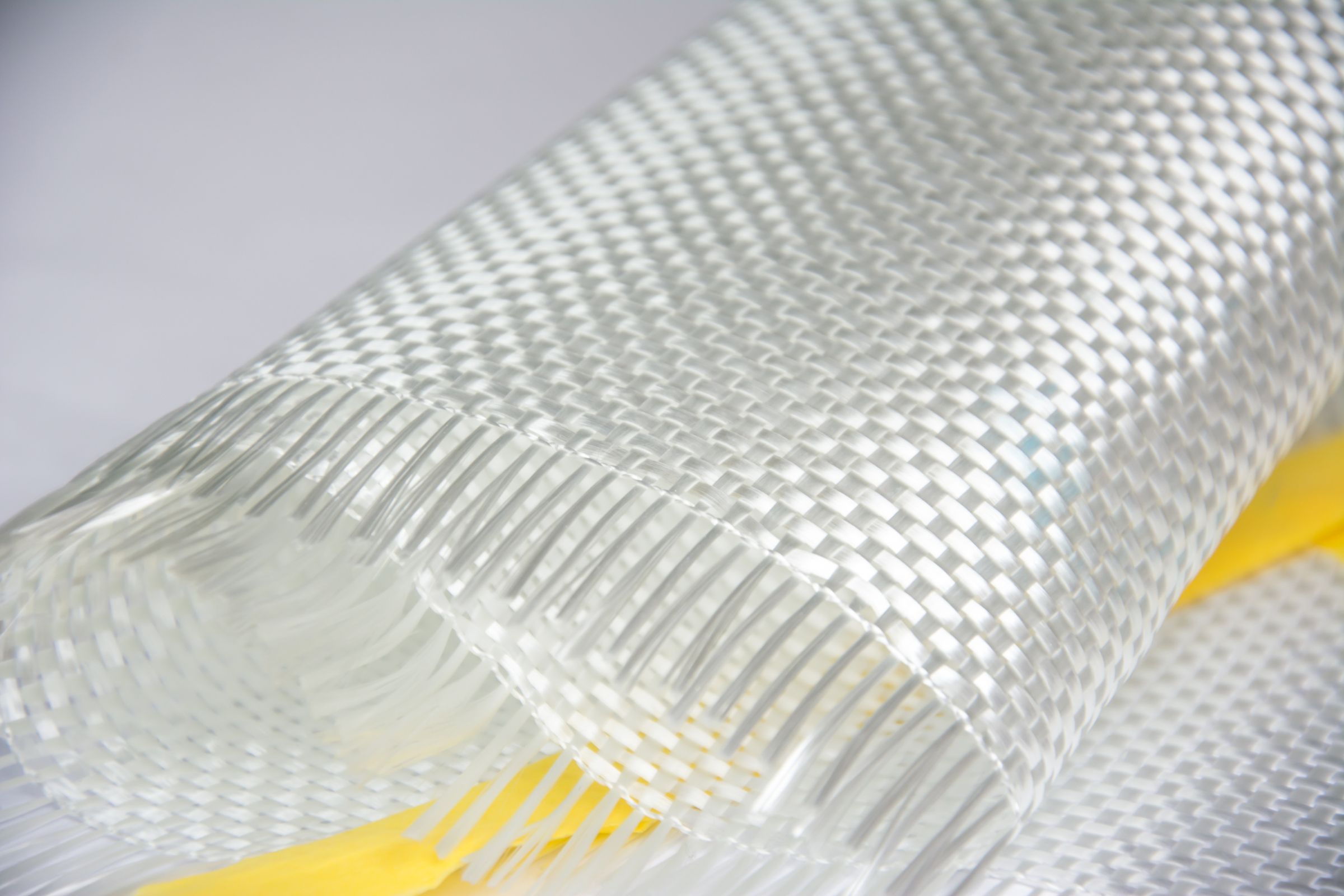

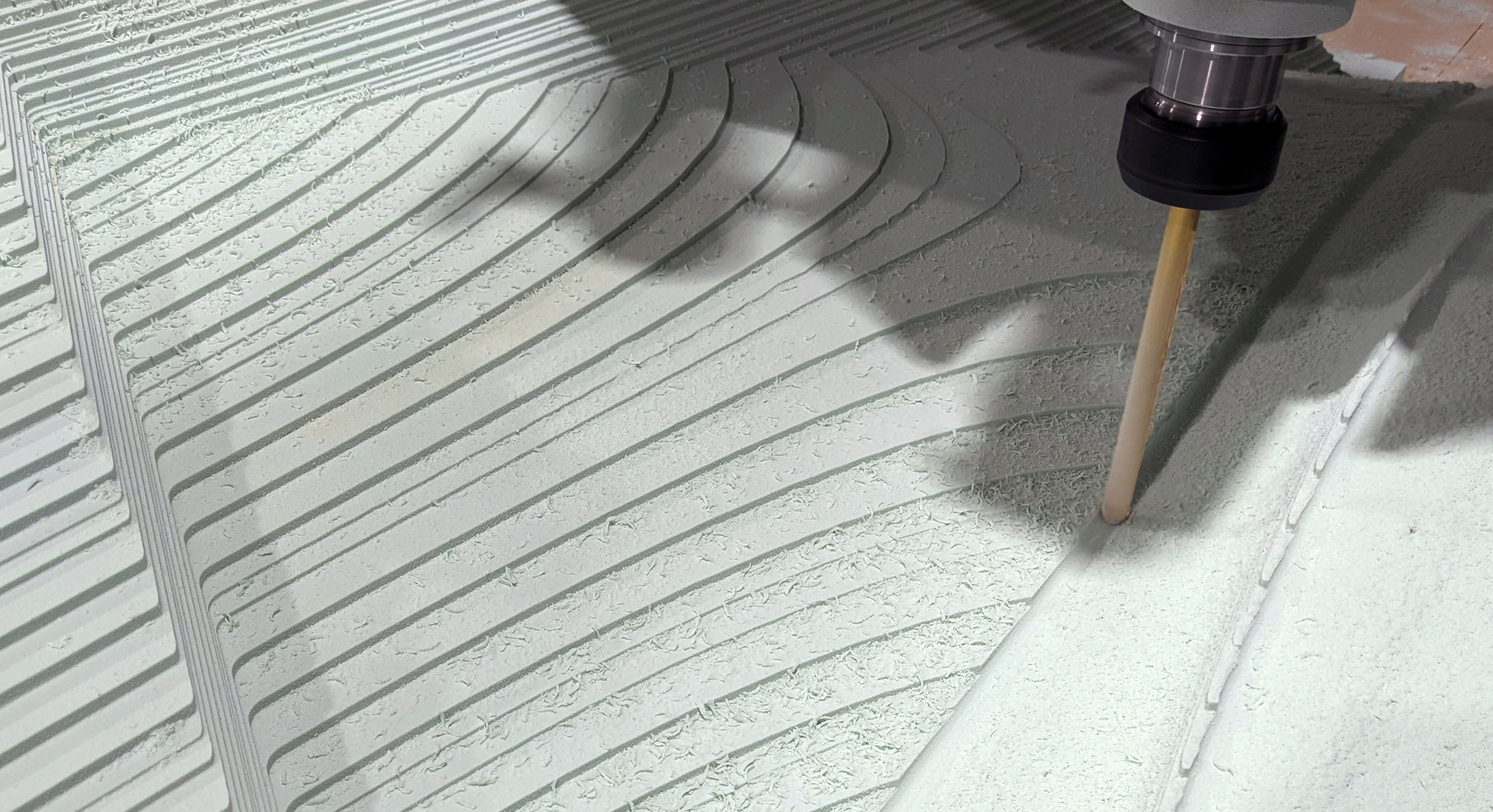

Revolutionizing Sustainable Construction with GFRC As the construction industry increasingly prioritizes sustainability, innovative materials like GFRC panels are taking center…

As a designer, working with architectural precast concrete offers an unparalleled amount of creative flexibility to create a truly unique product. This is what has precast concrete, particularly GFRC as a lighter and stronger concrete matrix, such an increasingly popular medium for sinks for any application. Whether for a major hotel lobby bathroom or a guest bathroom at an island beach house, a precast concrete sink can be functionally and aesthetically designed specifically for the space. However, concrete does have some constraints depending on the sink design that every designer should take into consideration. At Concreteworks East, we refine and assist the design team with their sink design to ensure no failures are present within the sink or with any of the plumbing fixtures, but within this article we are going to review some of these considerations to allow you as the designer to have a more technical knowledge as you approach your sink design.

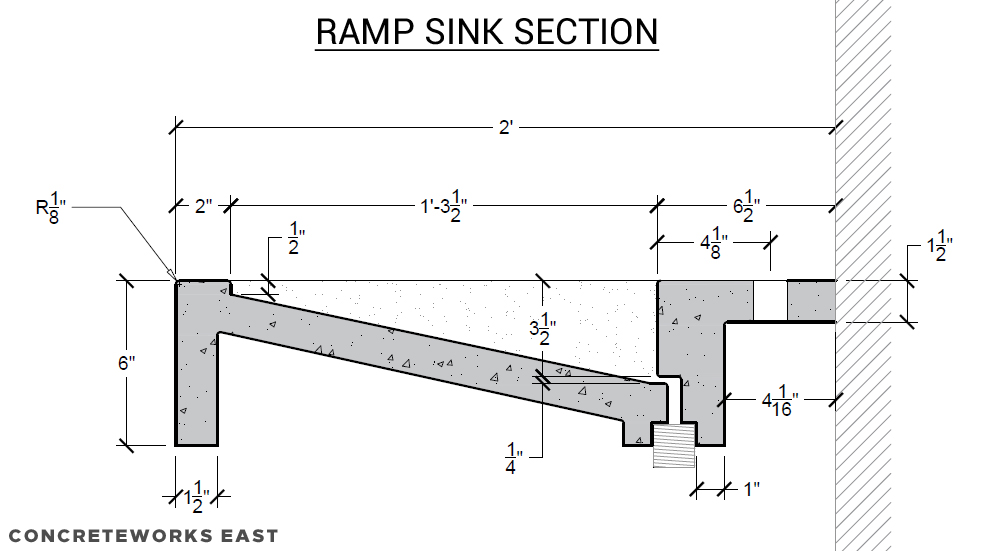

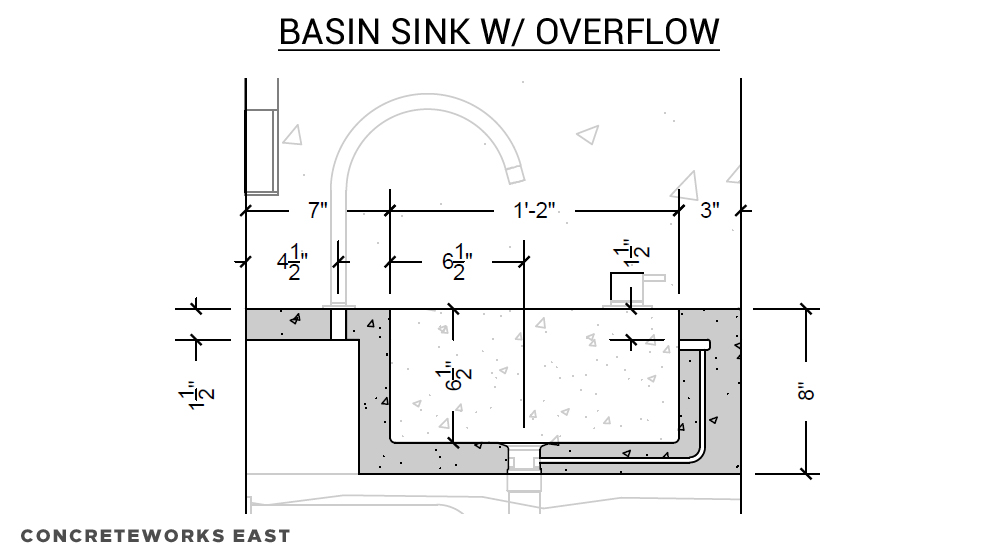

The most critical and common constraint in sink design is the thickness of the concrete. At any finished concrete surface there is 1.5 inches of concrete behind that surface so this must always be considered. Let’s break down the design approach:

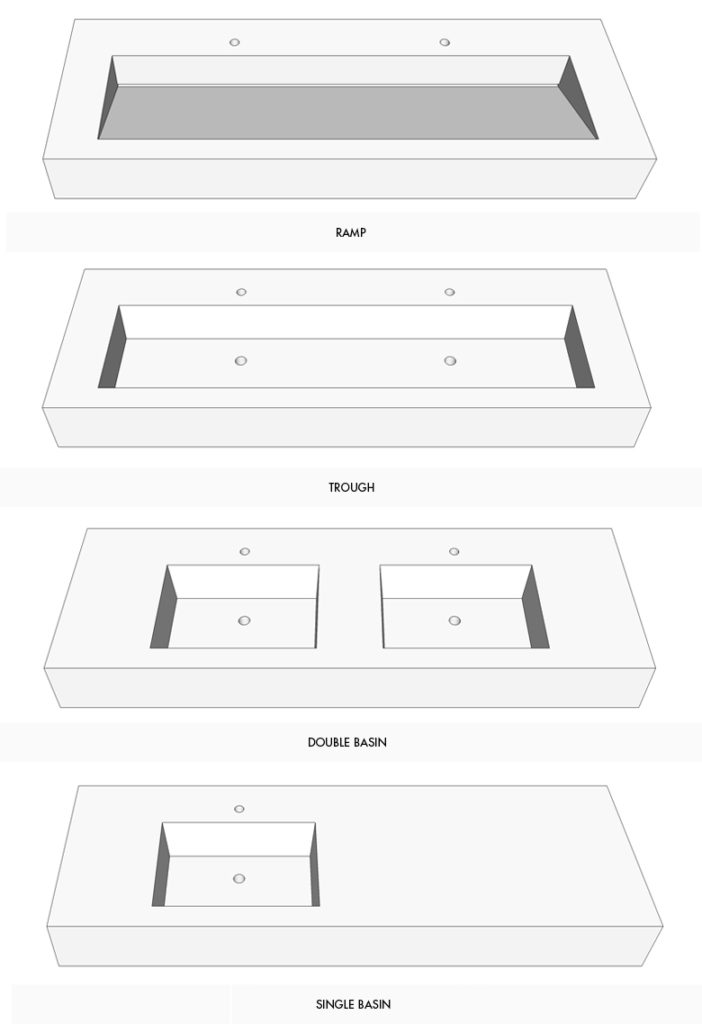

Sink Style: There are 3 common sink basin styles. A standard basin sink, which is a basic rectangular or circular bowl pitched to the center with a singular drain at the bottom. One basin is designed per user, so a his & hers sink for example would contain two basins. A trough sink, which is a long rectangular single bowl that spans across all users of the sink, typically contain one or more drains/faucets. Finally, a ramp sink, which pitches the water away from the user towards the rear of the sink into a narrow slot for drainage. No drain fixtures are visible in this sink design. Like a trough sink, a ramp sink typically contains a single ramp that spans across all users.

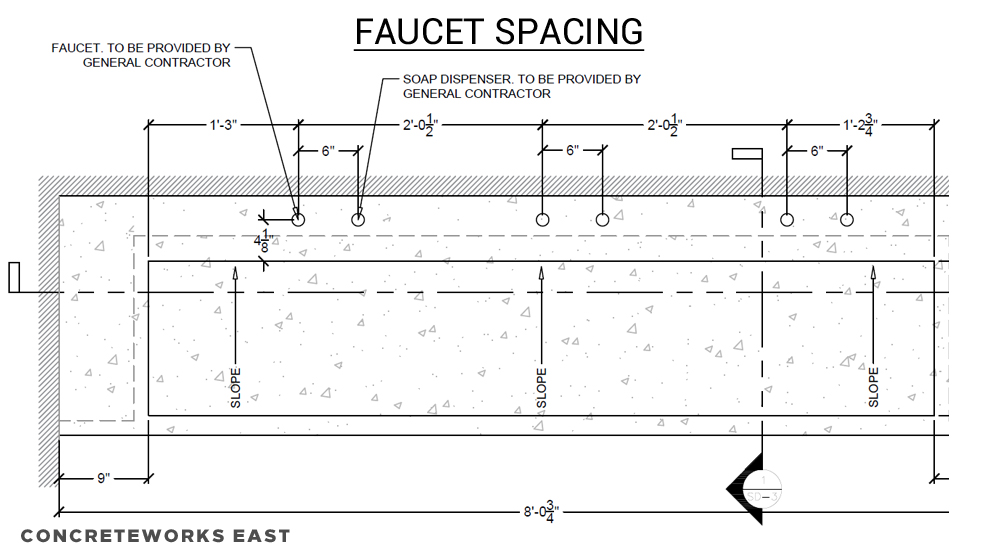

Sink Overall Width: Our max width for a monolithic concrete sink is 11ft. Any sink beyond that dimension would require seaming into multiple pieces. A seam cannot be placed through a sink basin, so a ramp or trough sink must be interrupted and split if the seam is placed within the sink basin.

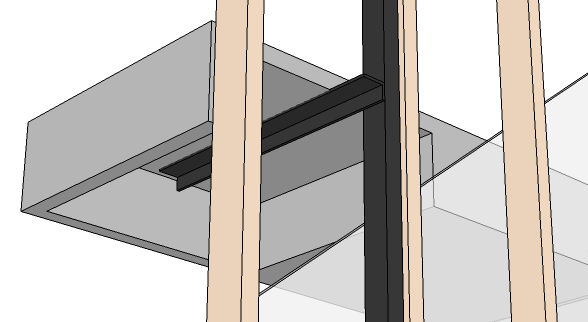

Sink Basin Width: The sink basin must be at least 3” shorter on each end than the overall sink width to accommodate the 1.5” concrete wall thickness at the side apron and sink basin wall. If you are designing a floating sink and need space between the sink basin and the end of the sink to place structural steel arms to support the sink, you must add the width of each steel arm to the 3” clearance needed.

Sink Apron Height: The sink apron is the vertical face at the front and sides of a sink. The sink apron can be as high as 16” or as small as 1.5”, which would represent the concrete thickness.

Sink Basin Depth: If you are designing a floating sink with no millwork or vanity underneath, your sink basin depth must be at least 2” shorter than you apron height for the underside of the sink to not be visible. If the sink is being placed in a vanity, this constraint does not matter, and your sink depth can be set to any dimension.

Sink Top Depth: The sink top width is constrained by a couple of elements:

No Overflow: The front of the sink basin must be 1.5” from the front edge of the sink.

or

Integral Overflow: Overflows on concrete sinks are integrated within the wall of the concrete on the vertical sink basin face closest to the user so that the overflow is not plainly visible. This integration requires extra thickness in that front wall. If you desire an overflow, the sink basin must be at least 3” from the front edge of the sink.

Faucet/Soap Dispensers: The sink top behind the sink basin is the most common mounting spot for faucets and soap dispensers. You must design enough space to mount the fixtures, considering both the finished face of the sink as well and the underside connections. The leading edge of a faucet must typically be no closer than 2” from the back edge of the sink basin as to allow room for the sink wall thickness as well as the mounting connection underneath. A soap dispenser with a soap storage container make require a lot more room to accommodate the container. This information can be found on the manufacturer’s specification sheet of the fixture. Typically, around 5”-6” of sink top space behind back edge of the sink basin is needed. If you are utilizing wall mount faucets, you could gain back some valuable space.

Drain: On a standard basin or trough sink, the drain is visible. The drain can be of any style or finish, it just must be able to mount on a 1.5” thick sink. Most drains do accommodate this thickness but be sure the check the manufacturer’s specification sheet to confirm. If you have an overflow within the sink, the drain must have an integrated overflow opening as well. The Vola A-62 is a great example of a pop-up drain with an integrated overflow.

These are just some of the basic and most common attributes of designing a concrete sink. The possibilities only continue from here, such as with integrated soap shelves, lighting niches, or towel chutes. At Concreteworks East, we want to bring your creative vision to life. If you need any assistance in design or want to pursue having a hand crafted unique sink fabricated for your project, please don’t hesitate to reach out to us at info@concreteworkseast.com or (732)-390-9944.